Maintenance scheduling is a process by which potential problems are identified and actions are devised to resolve them. A maintenance schedule template is a plan that includes who will do the work, what that work is and where it is, among other things. This is an essential part of any business that depends on equipment or machinery to deliver products or services.

Our free equipment maintenance schedule template creates an action plan to stay on top of your resources and ensure they’re fully functional when you need them. Download our free maintenance schedule template for Excel and improve your equipment’s performance and longevity.

Why You Need a Maintenance Schedule Template

A maintenance schedule template creates a consistent process that ensures equipment is always working properly. This prevents unexpected replacements and breakdowns, resulting in missed deadlines, late deliveries, unhappy customers and reduced profitability.

Also, using a maintenance schedule template allows technicians to detect problems early. This avoids lengthy unscheduled downtime and permits repairs to be done at optimal times. A maintenance schedule means the work is carried out on time and regularly. It organizes tasks to improve efficiency, speed up workflow, cut costs and prevent problems.

The secret to a successful maintenance schedule is regularity. Getting lost in the work and forgetting the maintenance creates trouble. Use project management software to avoid an unscheduled work stoppage and manage maintenance tasks. ProjectManager is award-winning project and portfolio management software with recurring tasks to ensure that scheduled maintenance never falls through the cracks. Turn any task into a recurring task and add the recurrence and whether it repeats daily, weekly, monthly or annually. Then use various project views like the kanban board to track progress while email and in-app notifications ensure you never miss scheduled maintenance. Get started with ProjectManager today for free.

When to Use This Maintenance Schedule Template

A preventative maintenance schedule template should be used regularly, and the frequency of scheduled maintenance can be varied. Sometimes it should be done daily while other scenarios require weekly or monthly maintenance. There’s even the odd case where machinery only needs to be checked once per year.

The machinery or equipment that’s employed will have instructions on its use, but also on how to maintain the piece. Be sure to follow those instructions. If it says every 90 days, then schedule maintenance for every three months. To neglect the manufacturer’s instructions is to risk breakdowns or worse, which will cost more than a short break for scheduled maintenance in the long run.

Who Should Use This Maintenance Schedule Template?

The maintenance schedule template for Excel is a great tool for management to plan its regular maintenance of machinery. The manager will follow the manufacturer’s instructions in terms of the frequency of maintenance and then allocate resources for the completion of those maintenance activities.

The team responsible for maintenance will also use this preventive maintenance schedule template to organize their work and make sure that the machinery and equipment are ready when they need it. Scheduled maintenance is not always done in-house. There are maintenance teams in-house and there are maintenance contractors who are given the work.

The bottom line is that maintenance schedule templates will go through a lot of hands. For example, the factory manager needs to be involved in scheduling the optimum maintenance period when machines can be shut down without negatively affecting production.

What Is Included in This Maintenance Schedule Template?

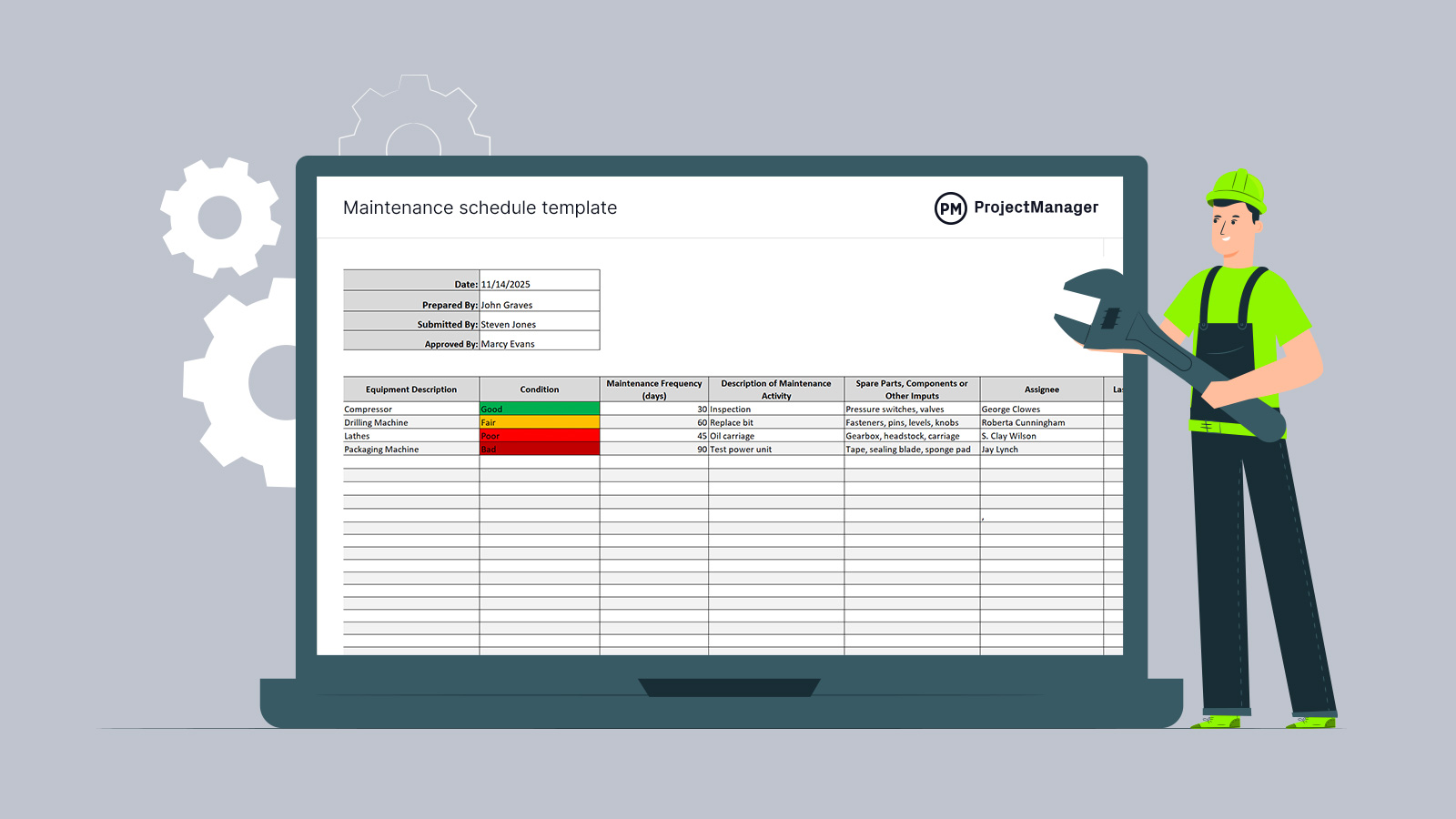

Once you’ve downloaded the free maintenance schedule template for Excel, you’ll see a partially filled-out list of equipment and more information. The preventative maintenance schedule template is fully customizable. Anyone can add or remove columns to conform to their maintenance schedule. The maintenance schedule has the basics, which are as follows.

- Equipment Description: Each line identifies one piece of equipment. For example, add the location of that piece of equipment if the facility is large.

- Condition: This column identifies the condition of the equipment. The pulldown menu is color-coded to make it easier to read at a glance. The four categories are: good, fair, poor and bad.

- Frequency of Maintenance (in Days): The maintenance schedule template then notes the frequency of maintenance for the particular piece of equipment. In the template, this is done in days, but it can be months if necessary.

- Description of Maintenance Activity: Each piece of equipment requires somewhat different maintenance. This cell will describe that specific maintenance in enough detail that it’s clear to the person responsible for it.

- Spare Parts, Components or Other Inputs: Parts might have to be replaced periodically or pieces need oil or some other type of maintenance. In this section of the schedule maintenance template, list those inputs.

- Assignee: Someone will be responsible for the equipment’s maintenance. List that person here.

- Last Maintenance Date: When maintenance is complete, record that date here.

- Next Maintenance Date: The date for the next maintenance is recorded here.

- Notes: Note anything important enough to include but didn’t fit in any previous sections.

Benefits of Using This Maintenance Schedule Template

A preventative maintenance schedule template is useful because it creates consistency in the maintenance planning process. A maintenance schedule that’s always formatted the same makes it easier to read and understand. Consistency in documentation is helpful for archiving paperwork, too.

Just having a maintenance schedule, though, is beneficial. For one, it reduces the risk of breakdowns that can interrupt operations, which is expensive. Another reason related to cost is that maintenance extends the lifespan of your assets.

By keeping a regular maintenance schedule, the equipment will run more efficiently. The less it’s maintained, the less optimal its performance. This slows down production and likely causes quality issues. Maintenance also adds efficiency to workforce management. It gives maintenance people a clearer, organized schedule to focus on upcoming tasks without being constantly pulled away to respond to emergencies.

Finally, a maintenance schedule template improves budget management. It provides a greater return on investment (ROI) from assets and prevents penalties for non-compliance. Planning maintenance helps forecast budgets more accurately and helps companies understand how much they need to spend on maintenance.

How to Create a Maintenance Schedule With ProjectManager

Project management software can help you manage your maintenance schedule better than a static template. ProjectManager is award-winning project and portfolio management software with features that can help you plan, manage and track your maintenance in real time. Recurring tasks are only part of larger maintenance scheduling features. Get started by taking a free 30-day trial of ProjectManager and then following these five steps.

1. List Maintenance Tasks, Due Dates & Duration

Begin with the Gantt chart. On the left-hand side is a spreadsheet to list all the maintenance tasks, one per row. Then add the start date for maintenance and end date as well as its duration. This will automatically populate on the right-hand side of the Gantt chart, which is a visual timeline, which provides a high-level overview of the maintenance schedule.

2. Assign Maintenance Tasks to Your Team

There is also a column in the Gantt to assign team members to individual tasks. When onboarding the team, set their availability, including PTO, vacation and global holidays, to make it easier to assign them tasks.

3. Estimate Costs

Another column on the Gantt chart captures the estimated cost of the maintenance. Use historical data and input from your team to get accurate estimates.

4. Set Recurring Tasks

Open a task card from the Gantt, kanban board, calendar, sheet or list view to set up when you want the task to come up again. This allows for regular maintenance not to fall through the cracks. As noted, email and in-app notifications alert users when recurring tasks are due.

5. Define a Priority Level

On the same task card, set the priority level so the maintenance team knows which tasks to do first and which can be done later. On the task card, you can also attach files and images, add a description of the work, add tags and more.

6. Track Maintenance Costs With Real-Time Dashboards

To ensure maintenance is done on time and within the estimated cost, toggle to the real-time dashboard. It collects live data and displays it on easy-to-read graphs and charts that show everything from time to cost and workload. Unlike lightweight tools, there’s no lengthy and complicated setup required.

More Free Maintenance Planning Templates

If you’re not ready to upgrade, ProjectManager has over 100 free project management templates for Excel and Word you can use to plan, schedule and track your team’s work. Here are some free maintenance planning-related templates available to download.

Work Order Template

Use this free work order template for Excel to create and track maintenance jobs. It also acts as an invoice when you’re contracting external maintenance workers. The free template describes the work, the hours and rate for that work all on one sheet.

Equipment Inventory Template

Maintaining equipment requires a thorough inventory. Use this free equipment inventory template to capture all your equipment on one sheet. It lists the location, acquisition details, monthly costs and much more.

Production Schedule Template

A maintenance plan must work in conjunction with a production schedule. Use this free production schedule template for Excel to balance supply and demand when producing a commodity and scheduling time for necessary maintenance.

Related Maintenance Content

There’s a lot more to say about maintenance schedules and planning. If you’re interested in reading more, our site publishes weekly blogs and tutorial videos and has many free templates to download. Here’s a selection of maintenance-related content.

- Total Productive Maintenance Essentials: 8 Things You Need to Know About TPM

- Manufacturing Operations Management Explained

- Equipment Inventory: A Quick Guide

ProjectManager is online project and portfolio management software that connects teams whether they’re in the office, on the factory floor or anywhere else. Everyone can share files, comment at the task level and stay updated with email and in-app notifications. Join teams at Avis, Nestle and Siemens who use our software to deliver successful projects. Get started with ProjectManager today for free.